Gasoline Generator Series

Technical Specifications

Power Range: 0.5-12kW

Noise Control: ≤62dB(A) @7m

Fuel Consumption: 1.2L/h @50% load

Starting Method: Electric/Pull-start dual mode

Core Performance

Military-grade crankshaft forging technology ensures continuous operation lifespan exceeding 4,000 hours. Intelligent frequency conversion technology controls voltage fluctuation within ±1.5%, providing stable power for precision equipment. IP54 protection rating enables all-weather operation in complex environments.

Application Fields

Widely used in emergency backup power, outdoor engineering power supply, and mobile communication base stations. Low-noise design suits field film shooting and residential temporary power supply. During Zhengzhou flood relief, 200 units operated continuously for 72 hours to support rescue operations.

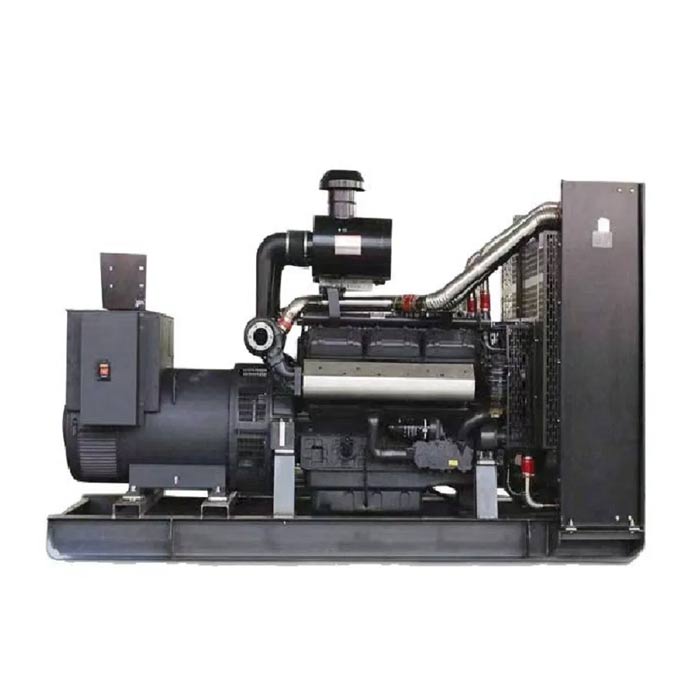

Diesel Generator Series

Technical Specifications

Power Range: 5-3000kW

Fuel System: High-pressure common rail technology

Fuel Consumption: 198g/kWh @75% load

Transient Response: ≤3s recovery

Industrial Reliability

Turbocharged intercooling technology maintains ≥95% power output at high altitudes. Military-grade anti-corrosion treatment passes 1,000-hour salt spray test for marine platforms. Cloud monitoring analyzes 32 operational parameters, predicting faults 48 hours in advance.

Engineering Applications

Primary power supply for Kazakhstan oil fields with single-unit runtime over 90,000 hours. 35 units ensured uninterrupted power during Hong Kong-Zhuhai-Macao Bridge construction. Silent models ≤75dB(A) comply with urban nighttime standards.

Gasoline Water Pump

Technical Specifications

Head Range: 16-50m

Peak Flow: 20-45m³/h

Solid Handling: Ø10mm particles

Fuel Type: 92# unleaded gasoline

Tank Capacity: 3.6L

Starting Method: Pull-start

Core Advantages

Lightweight design (26kg net weight) enables rapid deployment in confined spaces. Aluminum alloy pump body with self-cooling system allows 30-minute dry-run protection. Low-noise operation (≤75dB) meets residential nighttime requirements[5,6](@ref).

Typical Applications

Urban flood drainage (e.g., 20 units for Zhengzhou flood), garden irrigation, and construction site dewatering. Compact size fits small transport vehicles with fuel compatibility at standard stations[5,6](@ref).

Diesel Water Pump

Technical Specifications

Head Range: 15-100m

Peak Flow: 100-180m³/h

Solid Handling: Ø30mm particles

Fuel Type: 0#/-10# diesel

Tank Capacity: 12.5L (8h continuous operation)

Starting Method: Electric start

Heavy-Duty Design

Reinforced diesel engine (e.g., KC192FE model) delivers high torque output, supporting 7m suction head and 100m delivery head. Anti-clog impeller passes municipal sewage certification for fiber/sludge handling. IP68 rating withstands submersion/extreme conditions[7,8](@ref).

Engineering Applications

Large-scale flood control (e.g., Shenzhen Metro's 45-unit drainage network), mine water management (120h continuous operation in Myanmar), and firefighting water supply. Electric start + large tank ensures unmanned operation[7,8](@ref).

Smart Cabinet Energy Storage System

Core Parameters

Power Range: 50-200kW (parallel expandable)

Capacity Configuration: 100-400kWh/cabinet

Depth of Discharge: 90% DoD

System Efficiency: ≥94%

Protection Rating: IP54 (dust/water resistant)

Temperature Range: -20℃~+50℃

Smart Energy Management

Millisecond-response EMS enables dynamic capacity strategies and real-time charge/discharge optimization. Cluster-level BMS achieves ±10mV voltage precision monitoring, extending cell life 30% with active balancing. Modular design supports 20-cabinet parallel deployment.

Industrial Safety

Triple fire protection integrates temperature sensors with perfluorohexanone extinguishers, suppressing thermal runaway in 3 seconds. Cell-level shutdown prevents fault propagation (UL9540A certified). C4 anti-corrosion cabinet withstands coastal salt fog.

Multi-Scenario Validation

Nantong textile park: 12 units generated ¥1.8M annual peak-valley profits. Data center backup: 2N redundancy ensures 99.999% availability. Remote mines: Diesel-storage hybrid system cut fuel use by 40%.

Cummins Generator Set

Technical Specifications

Power Range: 50-3500kW

Response Time: ≤8s load acceptance

Overhaul Interval: ≥24,000 hours

Voltage Compatibility: 220V-13.8kV

Heavy-Duty Power System

QSK series engines synchronize with global maintenance systems for predictive upkeep. Parallel operation supports 20-unit synchronization (70MW total). -40℃ cold-start verified in Russian Arctic expeditions.

Global Project Validation

32 units for Saudi desalination plant (>100,000h fault-free). 15 units power Congo copper mine 24/7. Primary backup for 6 World Cup stadiums in Brazil.

Weichai Generator Set

Technical Specifications

Power Range: 15-1200kW

Fuel Consumption: ≤205g/kWh

Noise Level: 75-95dB(A)

Maintenance Cycle: 500 hours

Localized Innovation

High-pressure injection boosts 18% low-speed torque with ≤5% altitude power loss. IoT system monitors 32 parameters (98% fault预警 accuracy). Modular design cuts component replacement to 45 minutes.

National Projects

58 units on Qinghai-Tibet Railway (5,000m altitude). Hainan Free Trade Port construction (20M kWh supplied). China-Laos Railway substation dual-backup system.

Shangchai Generator Set

Technical Specifications

Power Range: 24-600kW

Transient Regulation: ≤±3%

Oil Consumption: ≤0.3g/kWh

Protection Rating: IP23

Urban Power Solution

Smart voltage regulation (≤0.5% fluctuation) meets data center requirements. Containerized noise reduction (68dB(A)) complies with residential nighttime limits. Quick-disassembly structure cuts maintenance time 40%.

Major Event Support

Shanghai Tower backup: 1,825 days continuous operation. Core zone power for G20 Summit in Hangzhou. Beijing Winter Olympics: 100% cold-start at -35℃.

Volvo Generator Set

Technical Specifications

Power Range: 64-550kW

Fuel Consumption: 194g/kWh @75% load

Transient Response: ≤3s recovery

Starting Temperature: -25℃ reliable start

Swedish Heavy-Duty Tech

Electronic injection + turbocharging (≤5% altitude loss). Military-grade crankshaft forging exceeds 30,000h continuous operation. IP23 rating for marine salt fog environments.

Global Validation

Kazakhstan oil fields: 32 units >90,000h no overhaul. Offshore wind platforms: ≤75dB(A) silent models. South African mines: 24/7 power guarantee.

Doosan Generator Set

Technical Specifications

Power Range: 50-2000kW

Fuel Consumption: 205g/kWh @75% load

Voltage Accuracy: ≤±0.5%

Protection Rating: IP22

Asia-Pacific Flagship

High-pressure common rail enables millisecond fuel control (≤0.25% voltage fluctuation). Modular design reduces overhaul time 40% with 80% parts commonality. Cloud platform monitors 32 real-time parameters.

Infrastructure Projects

Indonesia's Jakarta-Bandung HSR: 28 units deployed. Silent models for Ho Chi Minh commercial centers. African power projects: ≥95% power retention at high altitudes.

Yuchai Generator Set

Technical Specifications

Power Range: 20-3000kW

Fuel Consumption: ≤192g/kWh

Altitude Performance: ≥98% power at 2500m

Overhaul Interval: ≥12,000 hours

Localized Innovation

Four-valve technology + patented combustion chamber meets China III emission. Forged steel crankshaft reduces vibration 30%. Class H insulation withstands 180℃.

National Projects

Qinghai-Tibet Railway: 58 units across 23 stations. Anti-salt fog models for Hainan Free Trade Port. Dual-backup for China-Laos Railway substations (>30M kWh supplied).

Caterpillar Generator Set

Technical Specifications

Power Range: 100-4000kW

Response Speed: ≤5s load acceptance

Parallel Capability: 32-unit synchronization

Thermal Efficiency: ≥46.5%

Supercritical Technology

Circulating fluidized bed boiler achieves 46.5% thermal efficiency. Smart combustion system enables 20% deep peaking. Modular maintenance boosts efficiency 60% (>50,000h overhaul interval).

Energy Revolution

Red River 700MW ultra-supercritical project: efficient lignite combustion. 18 units for Middle East desalination plants. Brazilian data center: 72MW parallel system.

Perkins Generator Set

Technical Specifications

Power Range: 7-1811kW

Cooling System: Closed water circulation

Emission Standard: EPA Tier3/Euro III

Fuel Specification: 0#/-10# diesel

British Precision Engineering

1300/2300 series: Electronic management cuts fuel 15%. DCA4 additive prevents cylinder pitting (30% lifespan extension). 4,000 global service points (48h response).

Multinational Projects

40 units for Dubai Solar Park. -15℃ cold start in Congo mines. UK medical centers: 100,000-class clean power certification.

Deutz Generator Set

Technical Specifications

Power Range: 30-1000kW

Air-Cooling Tech: No radiator design

Power Density: +40% improvement

Cold Start: -35℃ reliable start

German Air-Cooling Tech

Liquid-free cooling eliminates freeze damage. Dry sump lubrication works at 30° tilt. Turbo intercooler maintains full power at 4,000m altitude.

Special Applications

Antarctic research stations. Mine slope drainage. Mobile field hospitals. Marine auxiliary power.

MTU Generator Set

Technical Specifications

Power Range: 150-3500kW

Transient Regulation: ≤±1%

Parallel Precision: Phase difference ≤0.5°

Overhaul Interval: ≥60,000 hours

Military-Grade Reliability

Full electronic injection (fuel atomization ≤5μm). Dual AVR backup (<10ms switch). Naval coating passes 2,000h salt spray test.

Critical Facility Protection

Frankfurt Airport runway construction. Norwegian subsea tunnels. Swiss nuclear plant backup. Saudi royal palace power.